WARDCRAFT

CONVEYORS

For over 113 years, Wardcraft Conveyor has provided standard and custom conveying solutions to the automotive, metal stamping, tool & die, machine tool, fastener, forging, die-cast, appliance, metal working, plastics and other material handling industries throughout the U.S., Canada & Mexico. We design, build and manufacture conveyance systems of all types, including steel hinge, belt and oscillating conveyors. Our experienced and creative staff of "imagineers" utilize modern technologies to meet the diverse conveying needs of all our clients with efficiency and excellence.

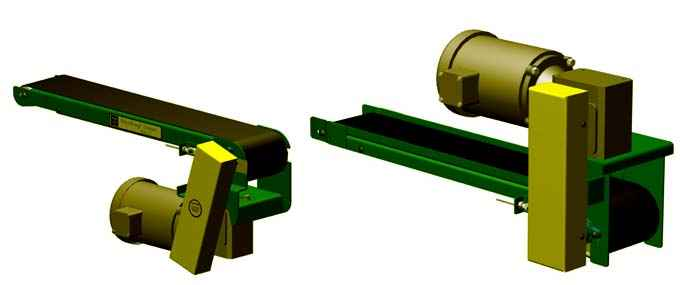

The

Model “SV” is for heavy-duty applications that require a

low profile conveyor. The original Slug-Vayor® first pioneered and developed

by Wardcraft Conveyor was designed for the metal stamping environment to carry

away slugs, parts and scrap created by die-presses, permitting continuous production

and reducing down-time. Now used where high durability and low profiles are

required. Available in a single unit or multiple-unit single drive configuration.

The

Model “SV” is for heavy-duty applications that require a

low profile conveyor. The original Slug-Vayor® first pioneered and developed

by Wardcraft Conveyor was designed for the metal stamping environment to carry

away slugs, parts and scrap created by die-presses, permitting continuous production

and reducing down-time. Now used where high durability and low profiles are

required. Available in a single unit or multiple-unit single drive configuration.

Model-MSV

was originally trademarked “Modular Slug-Vayor®” and was designed

specifically for lighter material handling. Whether your needs warrant a single

unit, application or multiple units with a single drive, MSV’s all have

a standard drive package that can be fitted for your product handling needs.

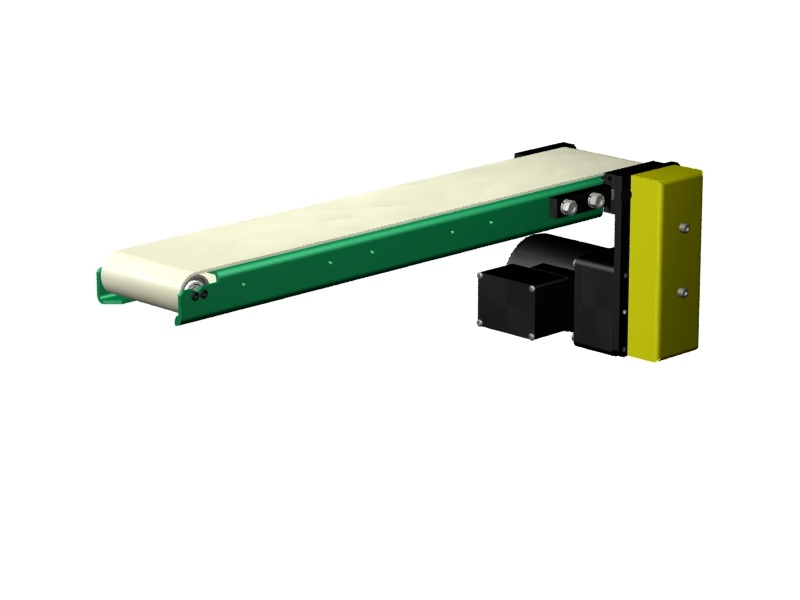

Model-MSV

was originally trademarked “Modular Slug-Vayor®” and was designed

specifically for lighter material handling. Whether your needs warrant a single

unit, application or multiple units with a single drive, MSV’s all have

a standard drive package that can be fitted for your product handling needs.

Our Model-MSV is characterized by a low-profile, 1 5/8" frame height (less

the high sides) and a frame width that is only 7/16" wider than the belt

itself. A large assortment of belt widths and lengths make the Modular Slug-Vayor®

a universal option to handle a variety of applications.

The

Model “PV”, originally known as the Parts-Vayor® is a

heavy duty conveyor that is primarily designed to move materials up an incline.

It utilizes a cleated belt to maintain accurate control and separation of materials

of any size and type. Standard Belt widths range from 6" to 36" to

meet most industrial needs, but larger sizes are available if required.

The

Model “PV”, originally known as the Parts-Vayor® is a

heavy duty conveyor that is primarily designed to move materials up an incline.

It utilizes a cleated belt to maintain accurate control and separation of materials

of any size and type. Standard Belt widths range from 6" to 36" to

meet most industrial needs, but larger sizes are available if required.

One

superior innovations is the Tray-Vayor2®—an

air-operated, beltless conveyance system that is designed to move product by

means of a “shaker” tray. The Tray-Vayor2® system is controlled

by a separate package that uses simple dials to control speed (up to 40’

per minute), direction of travel (for/rev) and air pressure (20 to 60 PSIG).

One

superior innovations is the Tray-Vayor2®—an

air-operated, beltless conveyance system that is designed to move product by

means of a “shaker” tray. The Tray-Vayor2® system is controlled

by a separate package that uses simple dials to control speed (up to 40’

per minute), direction of travel (for/rev) and air pressure (20 to 60 PSIG).

The

Model CV is an auger-type conveyor that has the capability to move virtually

any type of free-flowing material. From metal scraps and plastic shavings to

chemical remnants and food debris, the Chip-Vayor® can be utilized for a

variety of industrial applications. It is available in diameters as small as

4" up to 9" and has 2 configuration types. As with all our conveyors,

the dependable construction and simple design of the Chip-Vayor® assures

that it will operate with minimal difficulty for a long duration.

The

Model CV is an auger-type conveyor that has the capability to move virtually

any type of free-flowing material. From metal scraps and plastic shavings to

chemical remnants and food debris, the Chip-Vayor® can be utilized for a

variety of industrial applications. It is available in diameters as small as

4" up to 9" and has 2 configuration types. As with all our conveyors,

the dependable construction and simple design of the Chip-Vayor® assures

that it will operate with minimal difficulty for a long duration.

Steel

hinge conveyors are crafted to handle heavy-duty applications. They permit

continuous operation under even the most demanding conditions, minimizing downtime.

Common uses for steel hinge conveyors include stampings, forgings, fasteners,

die casting, recycling and scrap metal, as well as the removal of all types

of metal chips. Steel hinge conveyors can also be used in quench conveyor applications.

Steel hinge conveyors from Wardcraft Conveyor will stay running consistently.

We have the widest belt selection offered in the industry.

Steel

hinge conveyors are crafted to handle heavy-duty applications. They permit

continuous operation under even the most demanding conditions, minimizing downtime.

Common uses for steel hinge conveyors include stampings, forgings, fasteners,

die casting, recycling and scrap metal, as well as the removal of all types

of metal chips. Steel hinge conveyors can also be used in quench conveyor applications.

Steel hinge conveyors from Wardcraft Conveyor will stay running consistently.

We have the widest belt selection offered in the industry.

The

XTRA-Low Profile® is our slimmest conveyor offering yet. At a mere

1" thick, the XLP goes where many other conveyors can't. Best used for

light-duty applications, it can be fitted with belts from 2" to 12"

wide and 1' to 8' long. When a low-profile conveyance system is needed, look

no further than the XTRA-Low Profile®.

The

XTRA-Low Profile® is our slimmest conveyor offering yet. At a mere

1" thick, the XLP goes where many other conveyors can't. Best used for

light-duty applications, it can be fitted with belts from 2" to 12"

wide and 1' to 8' long. When a low-profile conveyance system is needed, look

no further than the XTRA-Low Profile®.

horizontal conveyance systems to meet the universal

needs of manufacturers. Whether it’s on the assembly line, in the inspection

room or for packaging department, Wardcraft horizontal conveyors utilize a wide

variety of belt materials to provide rugged and durable transport for any product.

In fact, our horizontal conveyors are so reliable, they can easily move scrap,

parts or other objects that are wider than the belt itself

horizontal conveyance systems to meet the universal

needs of manufacturers. Whether it’s on the assembly line, in the inspection

room or for packaging department, Wardcraft horizontal conveyors utilize a wide

variety of belt materials to provide rugged and durable transport for any product.

In fact, our horizontal conveyors are so reliable, they can easily move scrap,

parts or other objects that are wider than the belt itself

Horizontal

wire mesh conveyors are a cost-effective solution for efficient product

transport. However, unlike our standard horizontal conveyors, wire mesh is utilized

in place of PVC or polyurethane belts, excellent for hot parts or high impact

applications. This allows any fluids (like lubrications or oils) to drip clear

of the conveyor belt.

Horizontal

wire mesh conveyors are a cost-effective solution for efficient product

transport. However, unlike our standard horizontal conveyors, wire mesh is utilized

in place of PVC or polyurethane belts, excellent for hot parts or high impact

applications. This allows any fluids (like lubrications or oils) to drip clear

of the conveyor belt.

Contact us today to see how we can be of service to you.

3047 Brentmoor Dr./St. Charles, Missouri 63303/ phone: 636.939.3827 / email: vntur@vtech-1.com